Why AI-Powered CMMS Is the Future of Predictive and Smart Maintenance

In industrial settings and facility management, a single hour of unexpected downtime can translate into substantial financial losses, potentially reaching the millions. Maintenance teams have traditionally operated on a reactive “fix it when it breaks” model or a preventive “fix it because the calendar says so” schedule. But a significant change is underway as we approach 2026. The incorporation of Artificial Intelligence (AI) into Computerized Maintenance Management Systems (CMMS) is reshaping maintenance, shifting it from a necessary cost to a strategic advantage. Here’s why an AI-driven CMMS system is more than just a passing fad; it’s the future of intelligent maintenance.

Why AI-Driven CMMS System Is the Future

For years, conventional Computerized Maintenance Management Systems (CMMS) have been the backbone of maintenance teams, helping them stay on top of things and minimize downtime through scheduled tasks and resource allocation. However, AI-powered CMMS takes these advantages and amplifies them, incorporating sophisticated data analytics, automation, and the ability to learn and adapt over time.

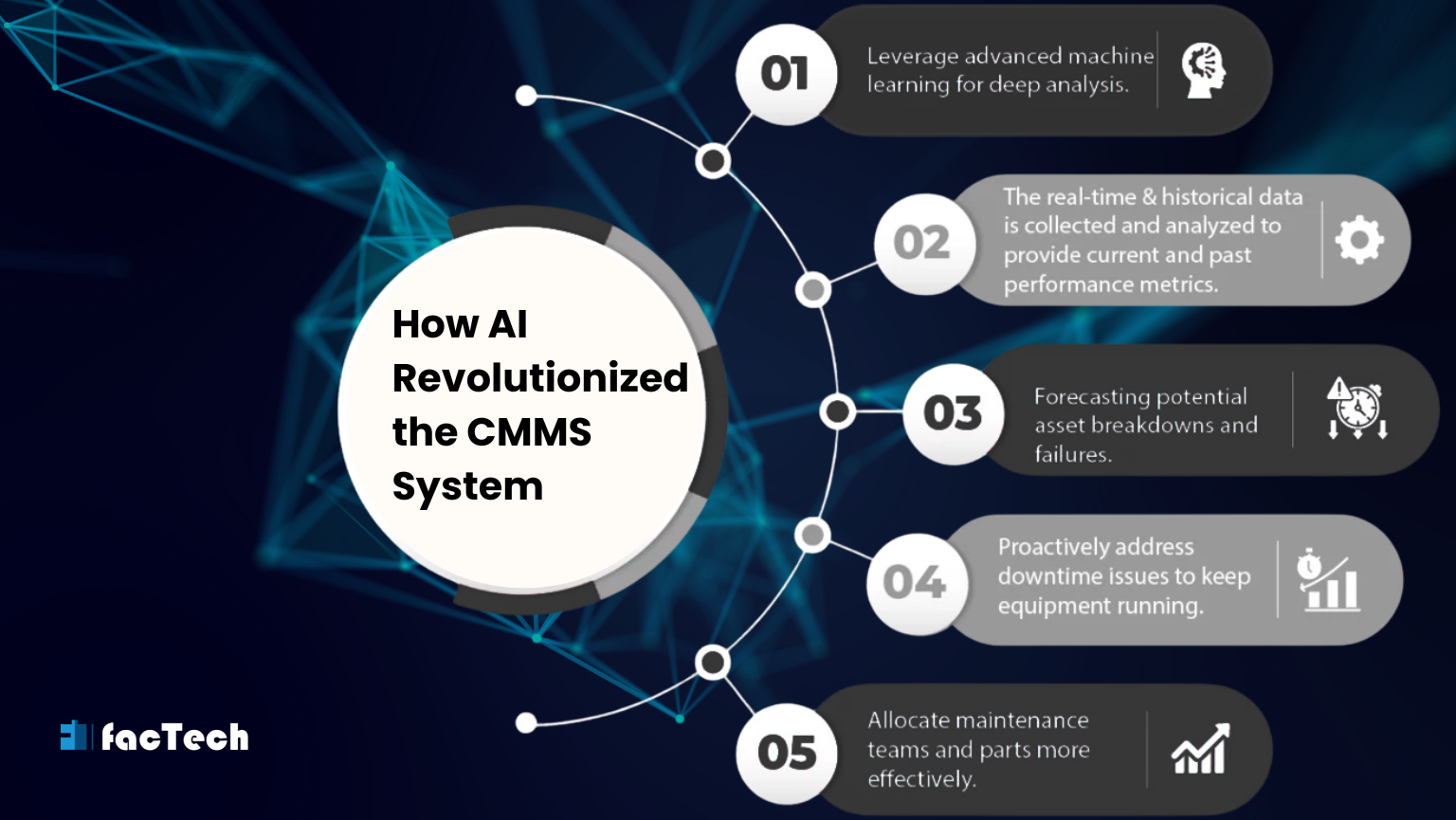

AI shifts maintenance from a reactive approach to a predictive one. The system constantly sifts through sensor data, past maintenance logs, and environmental conditions to foresee equipment failures before they happen. This proactive scheduling of maintenance helps teams avoid expensive breakdowns and prolong the lifespan of their assets.

Automation is a significant factor as well. AI intelligently prioritizes and allocates work orders, considering factors like urgency, location, and the technician’s skill set. This approach optimizes workforce efficiency and guarantees that critical problems receive prompt attention. The system continually learns and adjusts, refining its accuracy and the quality of its recommendations.

The future of maintenance is being reshaped by AI, making it smarter, quicker, and more efficient. Businesses that adopt AI-driven CMMS gain a competitive advantage by minimizing downtime, cutting repair costs, and increasing overall operational productivity. As technology advances, AI-powered maintenance systems will become a vital component of any progressive organization’s strategy to maximize asset performance and lower expenses.

Also read: The Ultimate 2026 Preventive Maintenance Plan: Free Templates & Checklists

How AI Revolutionized the CMMS System

Streamlined Workforce Planning and Skill Matching

Artificial intelligence can significantly enhance how maintenance resources are allocated. It does this by aligning technician skills with the tasks at hand, forecasting staffing requirements based on projected workloads, and pinpointing training needs to develop the workforce. The result is that the most qualified individual is always assigned to each job, which boosts the team’s overall efficiency and effectiveness.

Sustainability and the “Green” Maintenance Era

Sustainability has moved beyond a mere trend; it’s now a mandate. A well-designed CMMS (Computerized Maintenance Management System) can be a key asset in achieving ESG (Environmental, Social, and Governance) objectives.

If equipments are not maintained properly, they just waste the energy. Artificial intelligence can pinpoint when a machine is using too much power, a sign of friction or misalignment. Keeping assets in top shape allows businesses to cut both their carbon emissions and energy expenses. Plus, by extending the life of their equipment by 20–40%, companies also minimize the waste that comes from replacing things too soon.

Predictive Maintenance: The Key to Maximizing Uptime

Predictive maintenance stands out as the most significant use of AI within a CMMS. These AI algorithms sift through enormous datasets, encompassing everything from past maintenance logs to real-time sensor data collected by IoT devices—think temperature, vibration, pressure, and more—along with operational parameters. The goal? To spot those subtle patterns and anomalies. The result is a system that can forecast when a piece of equipment is likely to fail before it actually does. This foresight enables maintenance teams to plan interventions with pinpoint accuracy, which in turn dramatically cuts down on unplanned downtime, minimizes those costly emergency repairs, and streamlines how resources are used. Picture a scenario where critical equipment failures are the exception, not the norm.

Enhanced Decision-Making Through Data-Driven Insights

Unlike standard CMMS systems, which offer basic reports, AI takes raw data and turns it into something genuinely useful. AI algorithms are capable of uncovering the underlying reasons for repeated failures, highlighting weaknesses in maintenance procedures, and suggesting ways to boost asset performance. This more sophisticated analysis gives maintenance managers the tools to make smart, strategic choices, fostering ongoing improvement and ultimately, reducing costs over time.

How Factech’s AI-Powered CMMS Helps

Factech’s AI-driven CMMS is transforming management of facilities and assets. It moves away from the old, reactive approach to maintenance, replacing it with intelligent, predictive strategies. The platform uses AI algorithms and real-time data from IoT sensors to catch early signs of equipment problems—things like unusual heat or vibration—before they lead to a breakdown. This proactive approach can cut unplanned downtime by as much as half.

This “smart” system streamlines the entire maintenance process. It automatically creates work orders, manages spare parts, and assigns the best technician based on who’s available right now. In the end, Factech helps businesses get the most out of their assets, lower labor costs, and save energy by keeping everything running as efficiently as possible.

The bottom line

Shifting to an AI-driven CMMS means leaving behind the days of uncertainty and embracing accuracy. Maintenance managers can finally move beyond the reactive approach of constantly addressing immediate problems and begin proactively shaping their operations. Companies adopting this technology now are doing more than just cutting down on repair expenses; they’re constructing robust, enduring, and highly profitable operations capable of navigating the intricacies of today’s industrial world.

Also read: How Automated Maintenance Schedules Reduce Downtime by 30%+

FAQs

Q: What sets an AI-driven CMMS apart from the old-school variety?

While traditional systems stick to predetermined schedules, an AI-driven CMMS leverages real-time data to anticipate breakdowns and automate decisions, ideally before anything goes wrong.

Q: Does AI-powered maintenance actually make a difference when it comes to sustainability?

Absolutely. By pinpointing energy-wasting issues such as friction or misalignment, AI contributes to lower carbon emissions and can extend the lifespan of assets by 20–40%.

Q:How does the system ensure the right technician is assigned to a job?

The AI automatically analyzes work order urgency, technician location, and specific skill sets to ensure the most qualified individual is dispatched instantly.

Q: How do IoT sensors fit into a smart CMMS?

These devices serve as the system’s constant monitors, relaying data on temperature, vibration, and pressure to the AI for evaluation.

Q: What difference does Factech’s AI-driven CMMS make?

Factech’s proactive approach reduces unplanned downtime by 50% and labor and energy expenditures.